Blasting & Powder Coating in Rockhampton

Enquire Now in Rockhampton

Rejuvenate Your Metal Surfaces

At ADK Coatings, we deliver high-quality surface preparation and coating services to residential, commercial and industrial clients across Rockhampton. Our offerings include powder coating & abrasive blasting, all designed to enhance and protect your metal surfaces.

For projects involving large or stationary items, our mobile abrasive blasting service ensures expert results on-site, saving you the hassle of transport. By working with industry-leading brands such as Cerakote, Dulux, Oxytech and Senator, we guarantee durable finishes that meet the highest standards. Whether you need to restore metal surfaces, apply protective coatings or achieve a decorative finish, ADK Coatings has the expertise to meet your needs.

Call us today on 07 4979 1217 to learn more about our services!

What We Offer

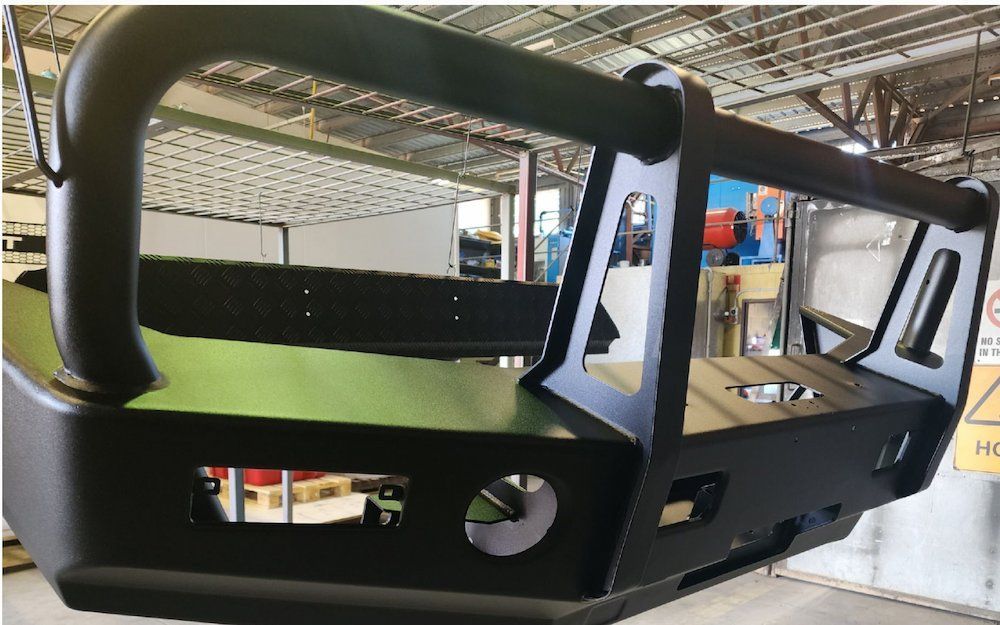

Powder coating transforms metal surfaces with vibrant, weather-resistant finishes in Rockhampton. It is ideal for gates, furniture and structural fixtures, combining durability with aesthetic appeal.

Our abrasive blasting service removes rust, paint and debris from metal surfaces, ensuring a clean base for restoration. This process is perfect for preparing machinery, railings or industrial components in Rockhampton.

We bring our mobile abrasive blasting expertise directly to your location in Rockhampton for large or fixed items. It’s an efficient solution for machinery, pipelines and heavy-duty projects.

Sand blasting effectively strips away paint, rust and grime, leaving metal surfaces clean and smooth. This service is ideal for preparing older items in Rockhampton for new coatings or restoration.

Cerakote ceramic coatings protect high-performance items like automotive parts, firearms and tools in Rockhampton. These advanced finishes resist heat, wear and corrosion for unmatched durability.

Why Choose Blasting & Coating?

Our surface preparation and coating services cater to a wide variety of needs across Rockhampton’s residential, commercial and industrial sectors:

- Residential Applications: Homeowners in Rockhampton turn to us for services that protect and enhance outdoor furniture, gates, fences and balustrades. Powder coating provides vibrant finishes that resist rust and wear, while abrasive blasting restores surfaces for a fresh start. From rejuvenating patio furniture to preserving metal gates, we deliver long-lasting solutions that combine style and functionality.

- Commercial Applications: Businesses in Rockhampton rely on our expertise to maintain and upgrade metal fixtures, railings and storefront features. Powder coating creates professional-grade finishes that withstand heavy use, while abrasive blasting ensures surfaces are clean and ready for restoration. Whether it’s enhancing signage, refurbishing outdoor seating or preparing industrial shelving, we provide tailored solutions that last.

- Industrial Applications: In Rockhampton’s industrial sector, we help protect heavy machinery, pipelines and structural components from corrosion and wear. Abrasive blasting removes contaminants to improve performance, while advanced coatings extend the lifespan of equipment. For large-scale projects, our mobile abrasive blasting service ensures efficient and seamless surface preparation on-site.

Enquire Now in Rockhampton

Contact Us

T. 07 4979 1217

Trading Hours

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Closed

- Sunday

- Closed

Frequently Asked Questions

What local areas do you service?

We provide services in Rockhampton and surrounding regions, including Yeppoon, Gladstone, Biloela and Bundaberg. With our mobile abrasive blasting service, we can handle on-site projects for larger or fixed items, ensuring professional results across the area.

How does powder coating compare to traditional paint?

Powder coating offers superior durability compared to traditional paint, as it resists chipping, fading and corrosion. It creates a thick, even finish that bonds securely to metal surfaces, providing long-lasting protection. Additionally, powder coating is more environmentally friendly, as it produces minimal waste during the application process.

What types of surfaces can be abrasive blasted?

Abrasive blasting can clean and prepare a variety of surfaces, including metal, concrete and some plastics. It is commonly used on machinery, pipelines and railings to remove contaminants like rust, paint and grime. The process can be tailored to suit the material and desired finish, ensuring optimal results.